Image 1 of 15

Image 1 of 15

Image 2 of 15

Image 2 of 15

Image 3 of 15

Image 3 of 15

Image 4 of 15

Image 4 of 15

Image 5 of 15

Image 5 of 15

Image 6 of 15

Image 6 of 15

Image 7 of 15

Image 7 of 15

Image 8 of 15

Image 8 of 15

Image 9 of 15

Image 9 of 15

Image 10 of 15

Image 10 of 15

Image 11 of 15

Image 11 of 15

Image 12 of 15

Image 12 of 15

Image 13 of 15

Image 13 of 15

Image 14 of 15

Image 14 of 15

Image 15 of 15

Image 15 of 15

Bioforcetech transforms organic streams into renewable energy and biochar

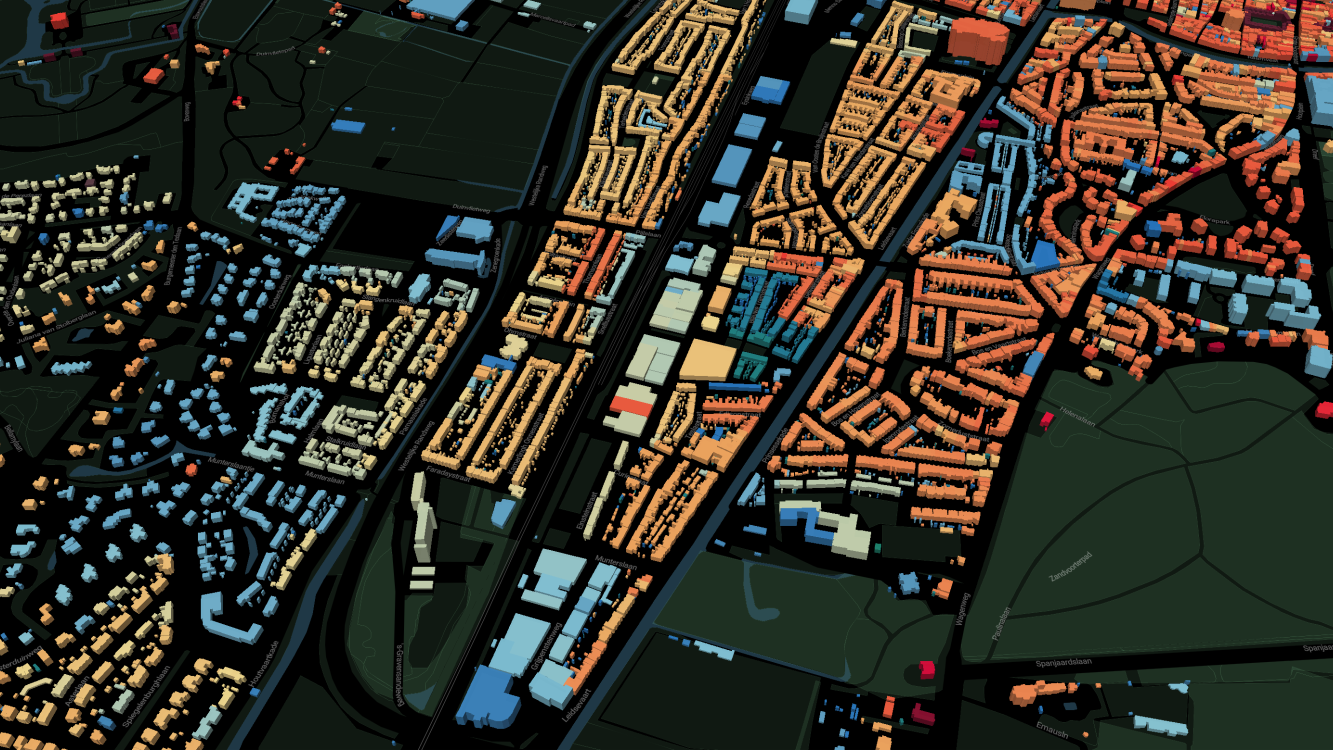

Bioforcetech Corporation is a company specialising in biomass management systems, founded with the mission to transform organic waste into valuable products while promoting sustainability and the circular economy. The company focuses on providing innovative, automated systems that convert biosolids and organic waste into renewable energy and biochar. Core values include sustainability, innovation, and responsibility, with a purpose to protect nature and human health by delivering zero waste solutions.

Location

Headquarters: South San Francisco, California, USA.

Primary manufacturing/operations locations: South San Francisco, California, USA, and Mezzago, Italy.

Note: Strategic locations in the USA and Italy to optimize local sourcing, distribution, and collaboration with industry partners.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating products that are fully recyclable and biodegradable.

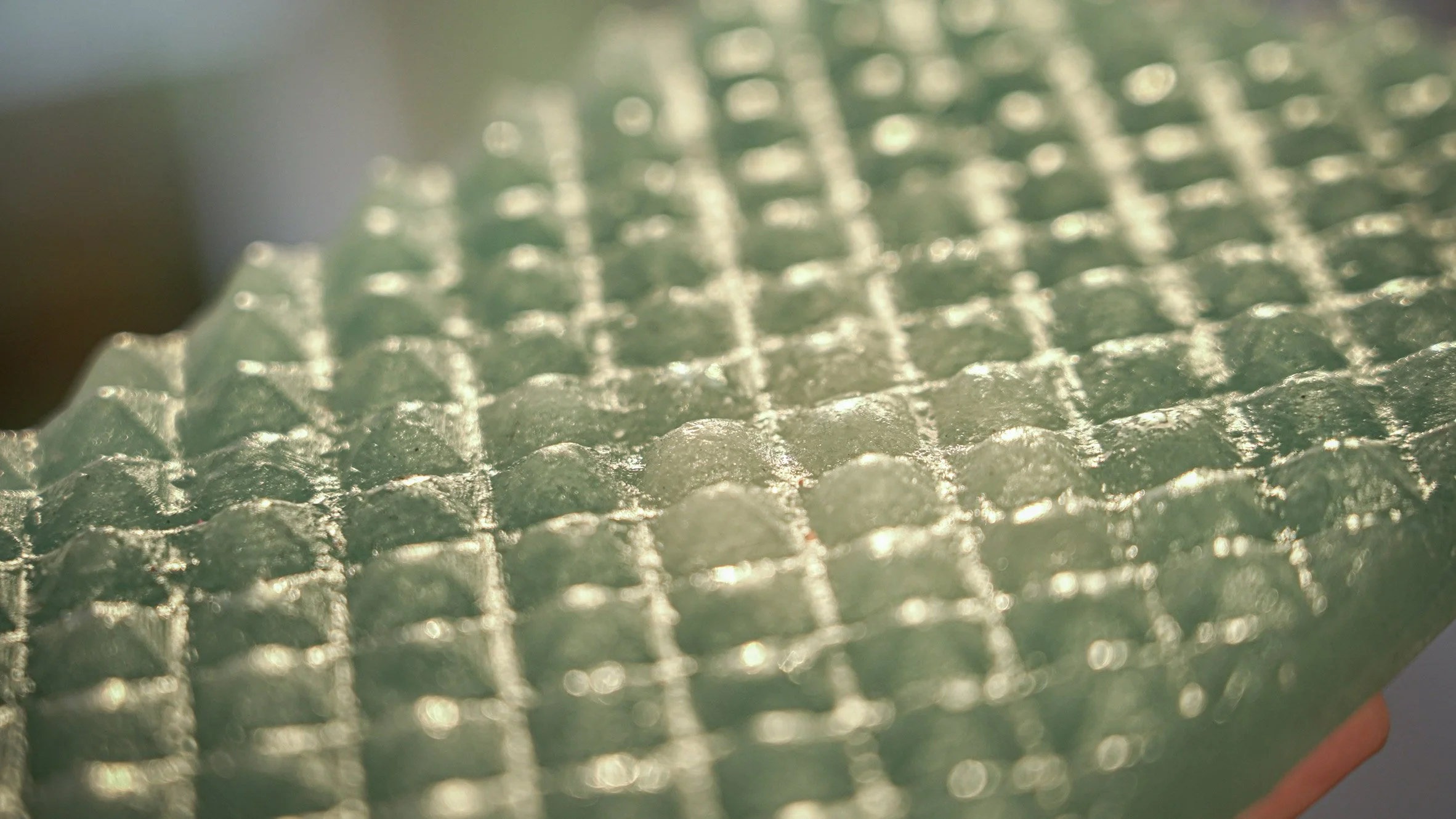

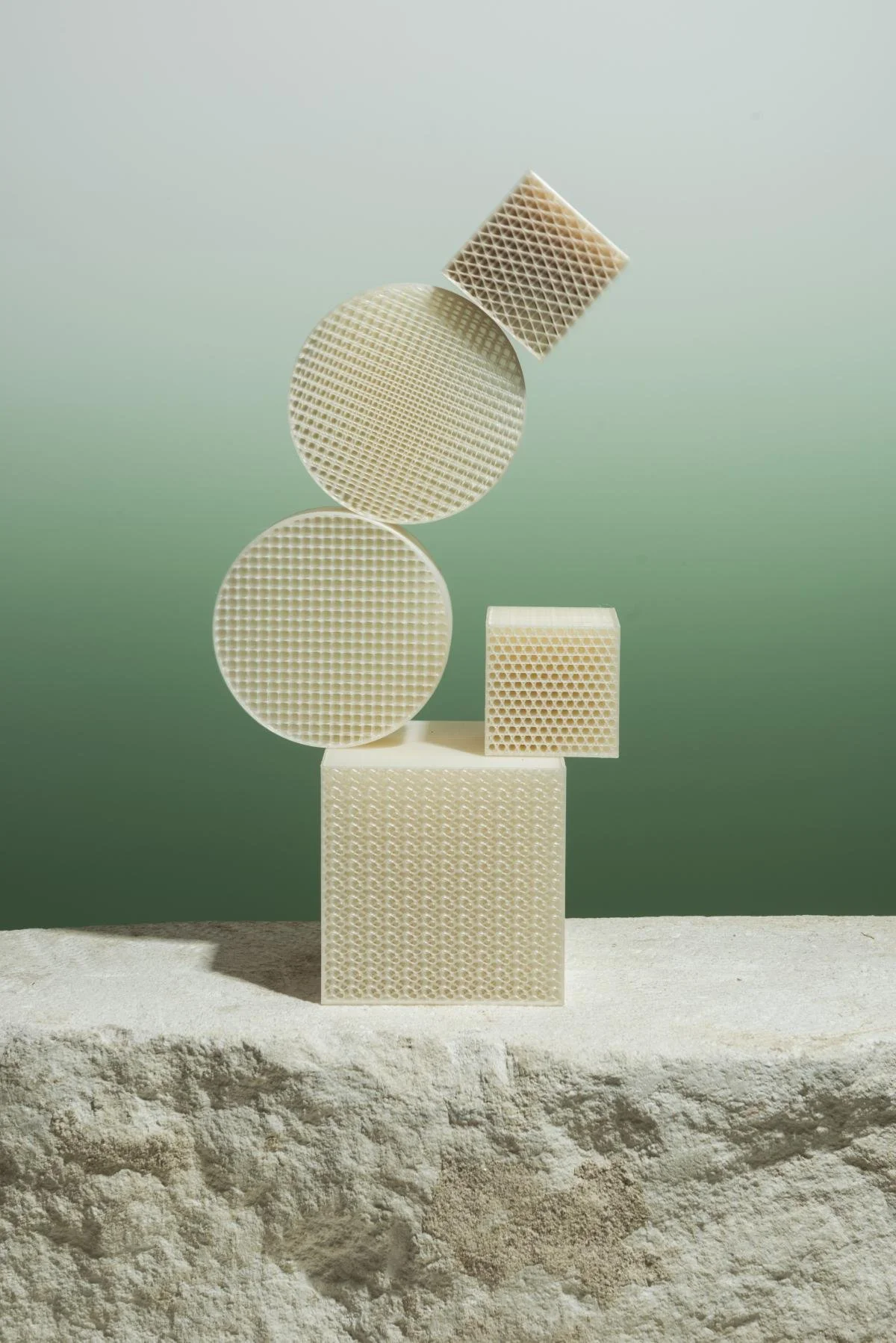

Key innovations: Development of the BioDryer and Pyrolysis systems that transform biosolids and organic waste into renewable energy and biochar. The BioDryer dries biosolids to produce a nutrient-rich Class A organic material, while the Pyrolysis process converts dried biosolids into biochar, a carbon-rich material with multiple uses.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on using locally sourced organic waste and sustainable production methods to minimize environmental impact and support local economies.

Pioneering Solutions

Flagship products: BioDryer, Pyrolysis system, and OurCarbon® Biochar.

Unique value propositions: High-quality, sustainable biomass management solutions that prioritize circularity, material reuse, and environmental responsibility. Bioforcetech's products are known for their ability to significantly reduce waste volume, generate renewable energy, and produce valuable by-products like biochar.

The Regenerative Future

R&D focus areas: Advancing biomass management technologies, optimizing production processes, and developing new applications for biochar and renewable energy.

Ambitious goals: To lead the waste management industry in sustainable practices, create zero-waste products, and inspire a shift towards a regenerative approach to organic waste management.

Fact Sheet

Commercial Availability: Products and services available globally through direct sales and partnerships with municipalities and waste management companies.

Circularity Rating: 5/5 (Strong focus on circular economy principles).

Cost Rating: 4/5 (Competitive with conventional waste management solutions, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled organic waste.

Designed for Disassembly: Yes, systems are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through sustainable materials and local production. The Bioforcetech process significantly reduces methane emissions by diverting organic waste from landfills.

Key Takeaway

Bioforcetech transforms the waste management industry through innovative, sustainable biomass management solutions, setting a benchmark for circularity and environmental responsibility.

Explore Further

Bioforcetech website: https://www.bioforcetech.com

Process overview: https://www.bioforcetech.com/process.html

Example product: OurCarbon® Biochar

Bioforcetech Corporation is a company specialising in biomass management systems, founded with the mission to transform organic waste into valuable products while promoting sustainability and the circular economy. The company focuses on providing innovative, automated systems that convert biosolids and organic waste into renewable energy and biochar. Core values include sustainability, innovation, and responsibility, with a purpose to protect nature and human health by delivering zero waste solutions.

Location

Headquarters: South San Francisco, California, USA.

Primary manufacturing/operations locations: South San Francisco, California, USA, and Mezzago, Italy.

Note: Strategic locations in the USA and Italy to optimize local sourcing, distribution, and collaboration with industry partners.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating products that are fully recyclable and biodegradable.

Key innovations: Development of the BioDryer and Pyrolysis systems that transform biosolids and organic waste into renewable energy and biochar. The BioDryer dries biosolids to produce a nutrient-rich Class A organic material, while the Pyrolysis process converts dried biosolids into biochar, a carbon-rich material with multiple uses.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on using locally sourced organic waste and sustainable production methods to minimize environmental impact and support local economies.

Pioneering Solutions

Flagship products: BioDryer, Pyrolysis system, and OurCarbon® Biochar.

Unique value propositions: High-quality, sustainable biomass management solutions that prioritize circularity, material reuse, and environmental responsibility. Bioforcetech's products are known for their ability to significantly reduce waste volume, generate renewable energy, and produce valuable by-products like biochar.

The Regenerative Future

R&D focus areas: Advancing biomass management technologies, optimizing production processes, and developing new applications for biochar and renewable energy.

Ambitious goals: To lead the waste management industry in sustainable practices, create zero-waste products, and inspire a shift towards a regenerative approach to organic waste management.

Fact Sheet

Commercial Availability: Products and services available globally through direct sales and partnerships with municipalities and waste management companies.

Circularity Rating: 5/5 (Strong focus on circular economy principles).

Cost Rating: 4/5 (Competitive with conventional waste management solutions, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled organic waste.

Designed for Disassembly: Yes, systems are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through sustainable materials and local production. The Bioforcetech process significantly reduces methane emissions by diverting organic waste from landfills.

Key Takeaway

Bioforcetech transforms the waste management industry through innovative, sustainable biomass management solutions, setting a benchmark for circularity and environmental responsibility.

Explore Further

Bioforcetech website: https://www.bioforcetech.com

Process overview: https://www.bioforcetech.com/process.html

Example product: OurCarbon® Biochar