Image 1 of 11

Image 1 of 11

Image 2 of 11

Image 2 of 11

Image 3 of 11

Image 3 of 11

Image 4 of 11

Image 4 of 11

Image 5 of 11

Image 5 of 11

Image 6 of 11

Image 6 of 11

Image 7 of 11

Image 7 of 11

Image 8 of 11

Image 8 of 11

Image 9 of 11

Image 9 of 11

Image 10 of 11

Image 10 of 11

Image 11 of 11

Image 11 of 11

Joris Laarman Lab create designs that are durable and long-lasting

Joris Laarman is a Dutch designer, artist, furniture maker, and entrepreneur based in Amsterdam, Netherlands. He founded Joris Laarman Lab in 2004 with his partner Anita Star. The studio was established with the mission to explore experimental designs inspired by emerging technologies. Laarman's current approach focuses on blending technology, art, and design, with a particular emphasis on the potential of 3D printing and digital fabrication. Core values include innovation, sustainability, and pushing the boundaries of design and technology, with a purpose to redefine the relationship between design, materials, and the environment.

Location

Headquarters: Amsterdam, Netherlands.

Primary manufacturing/operations locations: Various global locations for projects and collaborations.

The Circular Vision

Core circular economy principles: While not explicitly focused on circular economy, Laarman's work often incorporates principles of material efficiency and innovative production techniques that could contribute to sustainability.

Key innovations: Development of projects like the 3D-printed stainless-steel bridge in Amsterdam, showcasing the potential for creating adaptive, lightweight, and uniquely designed structures using digital fabrication.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on digital fabrication and 3D printing suggests potential for optimized material use and localized production.

Pioneering Solutions

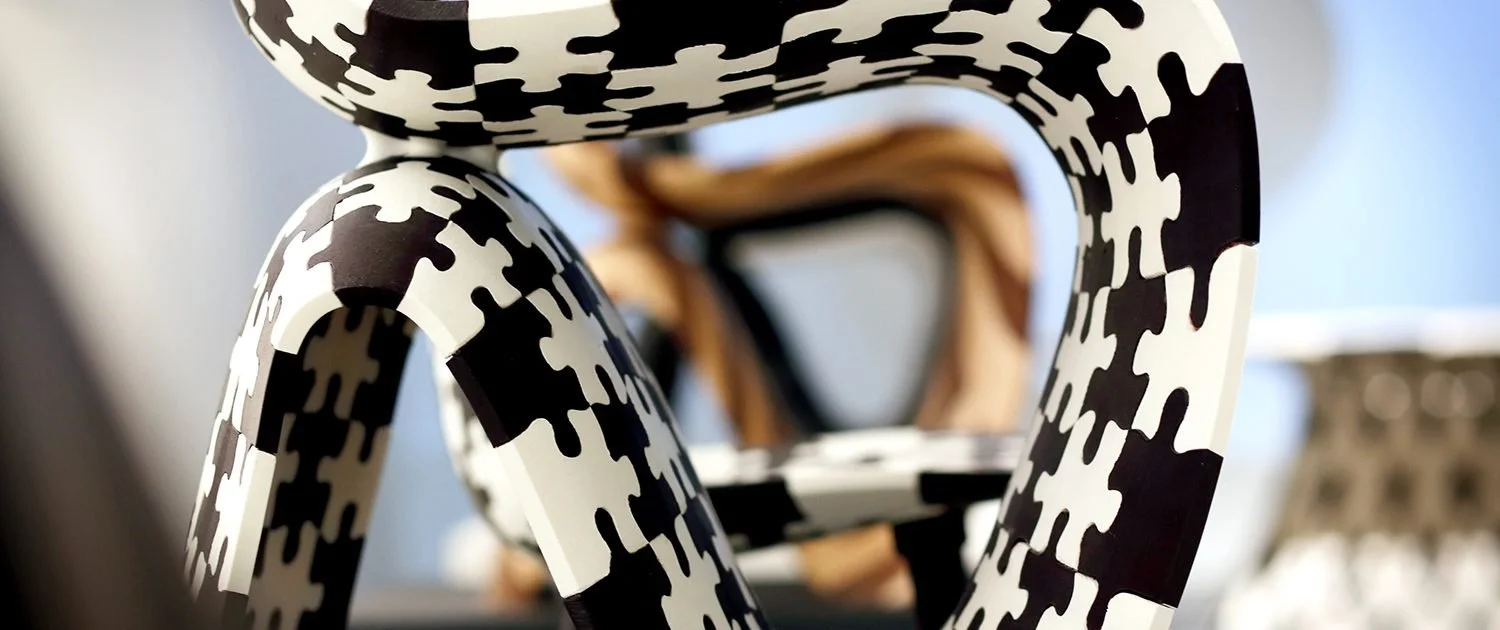

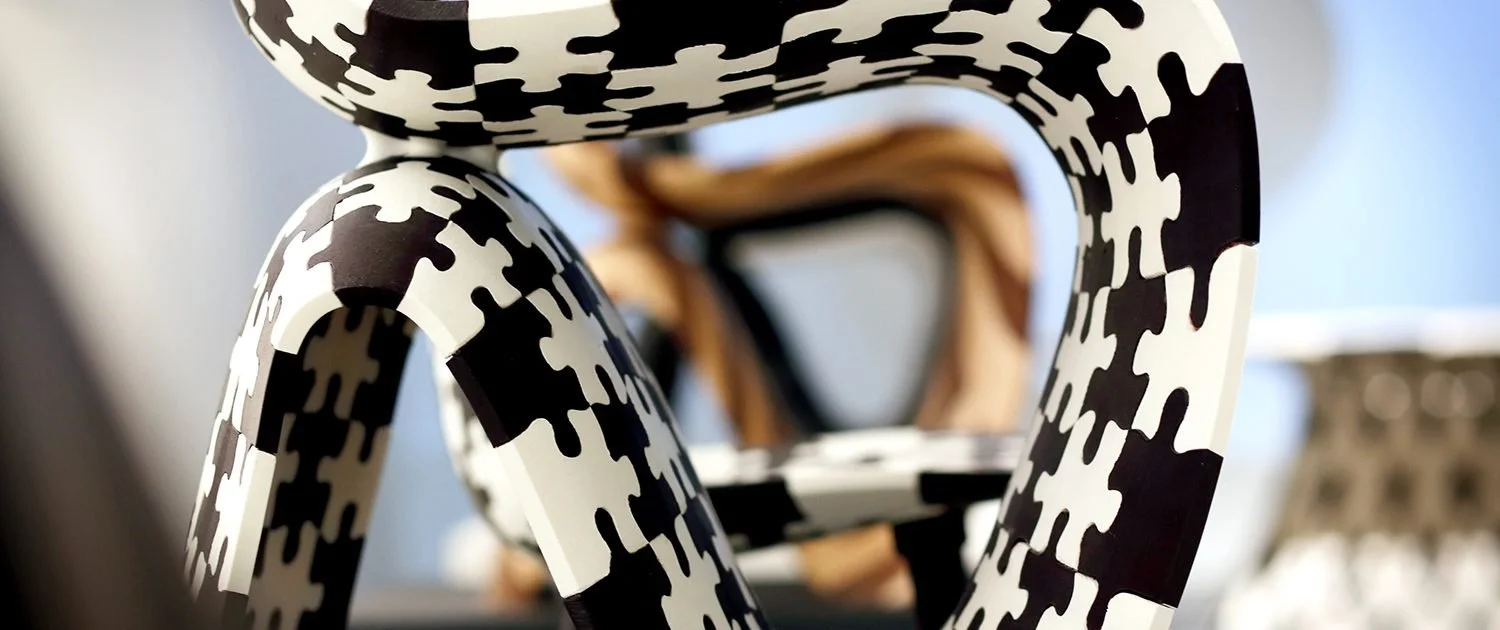

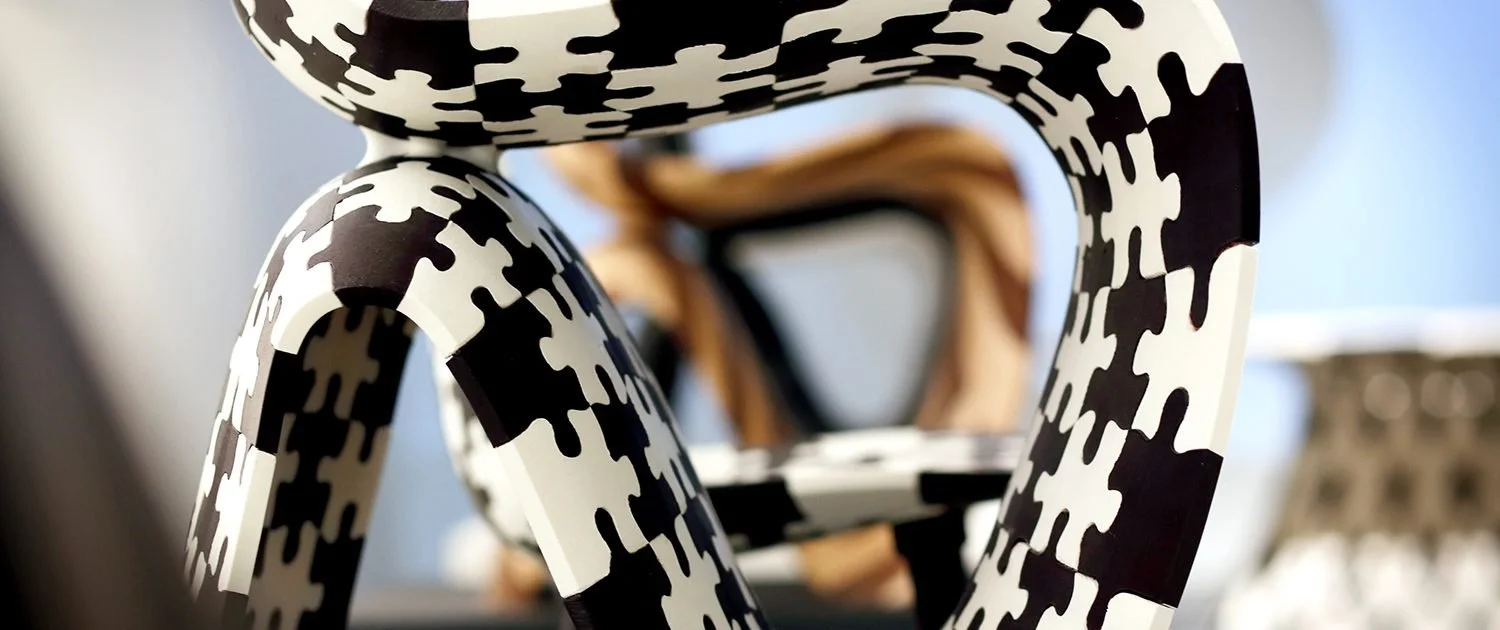

Flagship projects: Laarman's portfolio includes innovative projects such as the MX3D Bridge (3D-printed stainless steel bridge in Amsterdam), the Bone Furniture series (using 3D-optimization software for optimal construction), and the Digital Matter series (exploring new possibilities in 3D printing and digital fabrication).

The Regenerative Future

R&D focus areas: Advancing digital fabrication techniques, exploring new applications for 3D printing and sustainable materials, and developing solutions that further optimize material use and structural efficiency.

Ambitious goals: To lead the design industry in innovative practices, create novel production methods, and inspire a shift towards more efficient and technologically advanced design approaches.

Fact Sheet

Commercial Availability: Design services and products available through collaborations, exhibitions, and partnerships with institutions and businesses.

Circularity Rating: 4/5 (While not explicitly focused on circular economy, many projects incorporate innovative material use and production techniques that could contribute to sustainability).

Key Certifications: Wall Street Journal Innovator of the Year Award (2011), STARTS Prize awarded by the European Commission (2018).

Material Passport: Detailed material exploration and innovation in many projects, often focusing on 3D-printed and digitally fabricated materials.

Designed for Disassembly: Information not explicitly provided, but emphasis on digital fabrication suggests potential for adaptable and reconfigurable designs.

Carbon Performance: Information not explicitly provided, but focus on material efficiency and lightweight structures suggests potential for reduced environmental impact in some projects.

Key Takeaway

Joris Laarman transforms the design industry through innovative, technology-driven solutions that challenge conventional methods, setting a benchmark for exploring the intersection of digital fabrication, art, and design in contemporary practice.

Explore Further

Joris Laarman website: https://www.jorislaarman.com

Project example: MX3D Bridge

Joris Laarman is a Dutch designer, artist, furniture maker, and entrepreneur based in Amsterdam, Netherlands. He founded Joris Laarman Lab in 2004 with his partner Anita Star. The studio was established with the mission to explore experimental designs inspired by emerging technologies. Laarman's current approach focuses on blending technology, art, and design, with a particular emphasis on the potential of 3D printing and digital fabrication. Core values include innovation, sustainability, and pushing the boundaries of design and technology, with a purpose to redefine the relationship between design, materials, and the environment.

Location

Headquarters: Amsterdam, Netherlands.

Primary manufacturing/operations locations: Various global locations for projects and collaborations.

The Circular Vision

Core circular economy principles: While not explicitly focused on circular economy, Laarman's work often incorporates principles of material efficiency and innovative production techniques that could contribute to sustainability.

Key innovations: Development of projects like the 3D-printed stainless-steel bridge in Amsterdam, showcasing the potential for creating adaptive, lightweight, and uniquely designed structures using digital fabrication.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on digital fabrication and 3D printing suggests potential for optimized material use and localized production.

Pioneering Solutions

Flagship projects: Laarman's portfolio includes innovative projects such as the MX3D Bridge (3D-printed stainless steel bridge in Amsterdam), the Bone Furniture series (using 3D-optimization software for optimal construction), and the Digital Matter series (exploring new possibilities in 3D printing and digital fabrication).

The Regenerative Future

R&D focus areas: Advancing digital fabrication techniques, exploring new applications for 3D printing and sustainable materials, and developing solutions that further optimize material use and structural efficiency.

Ambitious goals: To lead the design industry in innovative practices, create novel production methods, and inspire a shift towards more efficient and technologically advanced design approaches.

Fact Sheet

Commercial Availability: Design services and products available through collaborations, exhibitions, and partnerships with institutions and businesses.

Circularity Rating: 4/5 (While not explicitly focused on circular economy, many projects incorporate innovative material use and production techniques that could contribute to sustainability).

Key Certifications: Wall Street Journal Innovator of the Year Award (2011), STARTS Prize awarded by the European Commission (2018).

Material Passport: Detailed material exploration and innovation in many projects, often focusing on 3D-printed and digitally fabricated materials.

Designed for Disassembly: Information not explicitly provided, but emphasis on digital fabrication suggests potential for adaptable and reconfigurable designs.

Carbon Performance: Information not explicitly provided, but focus on material efficiency and lightweight structures suggests potential for reduced environmental impact in some projects.

Key Takeaway

Joris Laarman transforms the design industry through innovative, technology-driven solutions that challenge conventional methods, setting a benchmark for exploring the intersection of digital fabrication, art, and design in contemporary practice.

Explore Further

Joris Laarman website: https://www.jorislaarman.com

Project example: MX3D Bridge