Image 1 of 14

Image 1 of 14

Image 2 of 14

Image 2 of 14

Image 3 of 14

Image 3 of 14

Image 4 of 14

Image 4 of 14

Image 5 of 14

Image 5 of 14

Image 6 of 14

Image 6 of 14

Image 7 of 14

Image 7 of 14

Image 8 of 14

Image 8 of 14

Image 9 of 14

Image 9 of 14

Image 10 of 14

Image 10 of 14

Image 11 of 14

Image 11 of 14

Image 12 of 14

Image 12 of 14

Image 13 of 14

Image 13 of 14

Image 14 of 14

Image 14 of 14

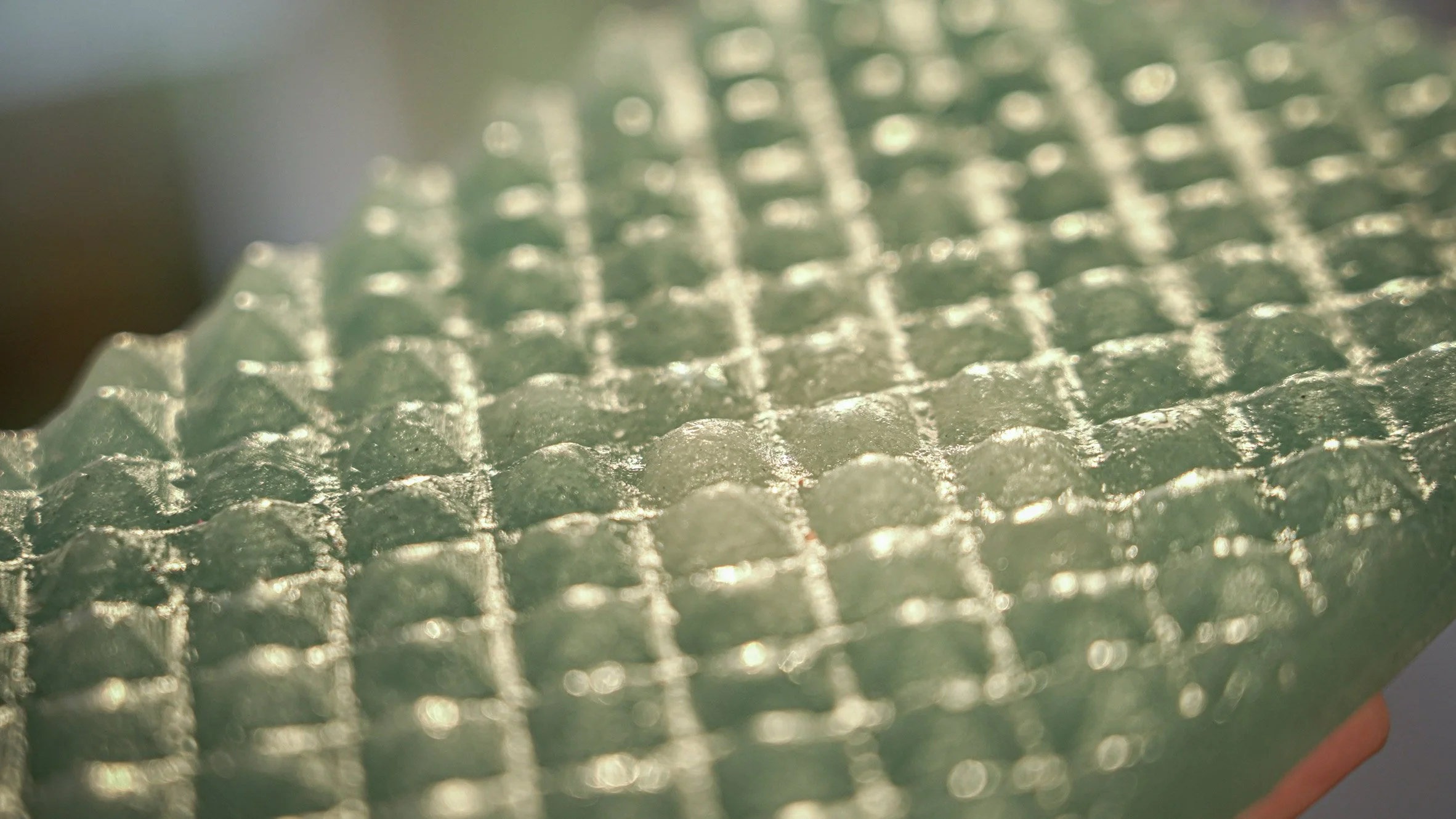

Kenoteq K-BRIQ is made from inert recycled input materials

Kenoteq is a Scottish company founded by Dr. Sam Chapman and Professor Gabriela Medero, spun out from Heriot-Watt University in 2019. The company was established with the mission to create ultra-low carbon sustainable building materials from recycled construction and demolition waste. Kenoteq's current mission focuses on providing innovative, high-performing materials that contribute towards net zero carbon targets and support local circular waste solutions. Core values include sustainability, innovation, and responsibility, with a purpose to revolutionize the construction industry through circular economy practices.

Location

Headquarters: Edinburgh, Scotland, United Kingdom.

Primary manufacturing/operations locations: Various locations across the UK, with plans for international expansion.

Note: Strategic location in Edinburgh to optimize local sourcing, distribution, and collaboration with industry partners.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating products that are fully recyclable.

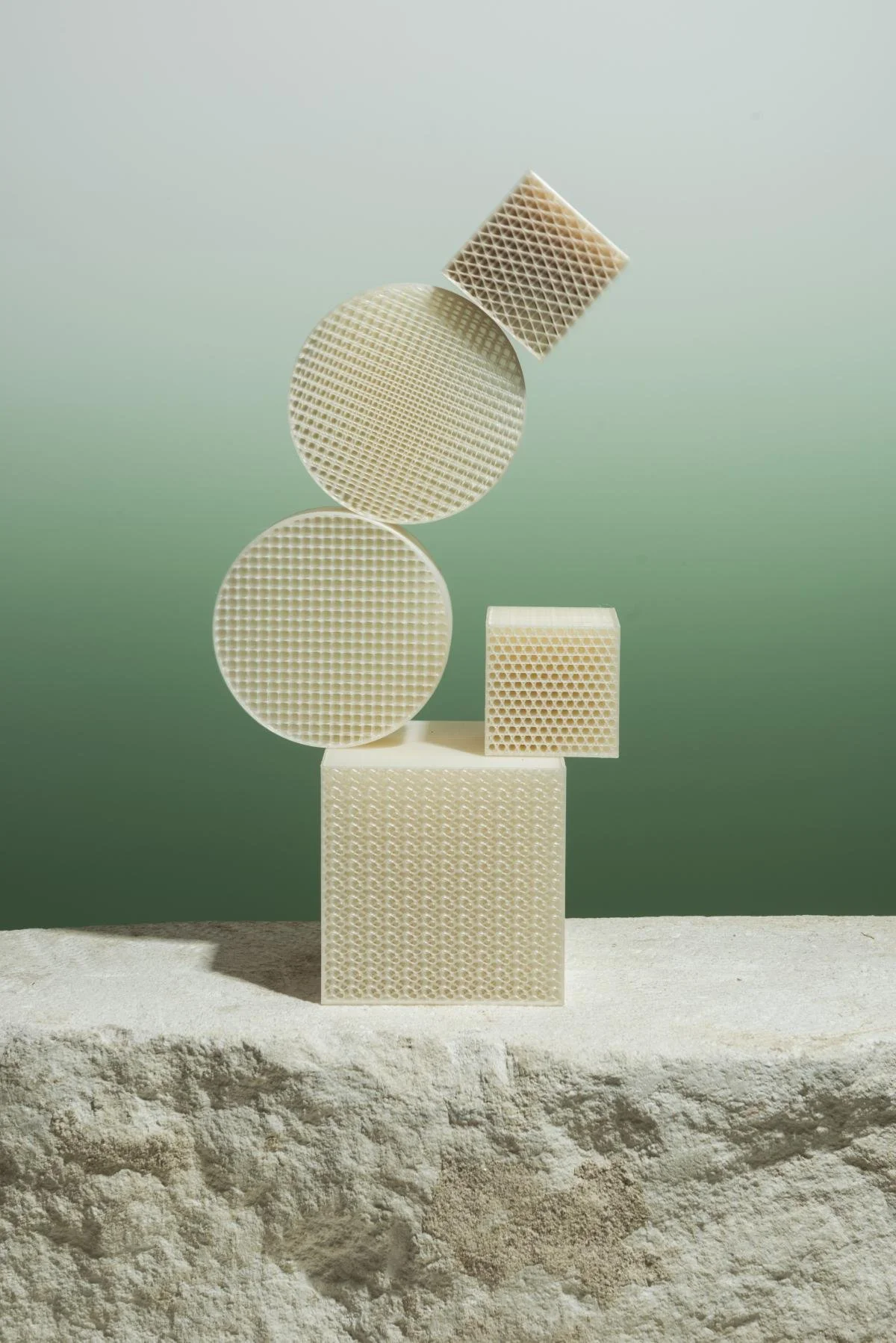

Key innovations: Development of the K-BRIQ®, an unfired brick made from over 90% recycled construction and demolition waste, using a patented low-energy, no-waste production process.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on using local waste materials and production to minimize environmental impact and support local economies.

Pioneering Solutions

Flagship products: K-BRIQ® and K-SLIP™.

Unique value propositions: High-quality, sustainable building materials that prioritize circularity, material reuse, and environmental responsibility. The K-BRIQ® boasts the lowest embodied carbon of any commercially available brick, with 95% less embodied carbon than traditional clay bricks.

The Regenerative Future

R&D focus areas: Advancing recycling technologies, optimizing production processes, and developing new applications for recycled materials.

Ambitious goals: To lead the construction industry in sustainable practices, create zero-waste products, and inspire a shift towards a regenerative built environment.

Fact Sheet

Commercial Availability: Products available through direct sales and partnerships with distributors.

Environmental Product Declaration (EPD): Available, providing transparency on environmental impacts.

Circularity Rating: 5/5 (Designed for full circularity).

Key Certifications: UK and US patents granted, European and Canadian patents pending. Product certification in the UK, Europe, and the US is underway.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of over 90% recycled construction and demolition waste.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through sustainable materials and local production. The K-BRIQ® produces 95% less embodied carbon than traditional clay bricks.

Key Takeaway

Kenoteq transforms construction and demolition waste into high-quality, sustainable building materials, setting a benchmark for circularity and environmental responsibility in the construction industry.

Explore Further

Kenoteq website: https://www.kenoteq.com

Sustainability overview: https://www.kenoteq.com/about

Kenoteq is a Scottish company founded by Dr. Sam Chapman and Professor Gabriela Medero, spun out from Heriot-Watt University in 2019. The company was established with the mission to create ultra-low carbon sustainable building materials from recycled construction and demolition waste. Kenoteq's current mission focuses on providing innovative, high-performing materials that contribute towards net zero carbon targets and support local circular waste solutions. Core values include sustainability, innovation, and responsibility, with a purpose to revolutionize the construction industry through circular economy practices.

Location

Headquarters: Edinburgh, Scotland, United Kingdom.

Primary manufacturing/operations locations: Various locations across the UK, with plans for international expansion.

Note: Strategic location in Edinburgh to optimize local sourcing, distribution, and collaboration with industry partners.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating products that are fully recyclable.

Key innovations: Development of the K-BRIQ®, an unfired brick made from over 90% recycled construction and demolition waste, using a patented low-energy, no-waste production process.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on using local waste materials and production to minimize environmental impact and support local economies.

Pioneering Solutions

Flagship products: K-BRIQ® and K-SLIP™.

Unique value propositions: High-quality, sustainable building materials that prioritize circularity, material reuse, and environmental responsibility. The K-BRIQ® boasts the lowest embodied carbon of any commercially available brick, with 95% less embodied carbon than traditional clay bricks.

The Regenerative Future

R&D focus areas: Advancing recycling technologies, optimizing production processes, and developing new applications for recycled materials.

Ambitious goals: To lead the construction industry in sustainable practices, create zero-waste products, and inspire a shift towards a regenerative built environment.

Fact Sheet

Commercial Availability: Products available through direct sales and partnerships with distributors.

Environmental Product Declaration (EPD): Available, providing transparency on environmental impacts.

Circularity Rating: 5/5 (Designed for full circularity).

Key Certifications: UK and US patents granted, European and Canadian patents pending. Product certification in the UK, Europe, and the US is underway.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of over 90% recycled construction and demolition waste.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through sustainable materials and local production. The K-BRIQ® produces 95% less embodied carbon than traditional clay bricks.

Key Takeaway

Kenoteq transforms construction and demolition waste into high-quality, sustainable building materials, setting a benchmark for circularity and environmental responsibility in the construction industry.

Explore Further

Kenoteq website: https://www.kenoteq.com

Sustainability overview: https://www.kenoteq.com/about