Image 1 of 9

Image 1 of 9

Image 2 of 9

Image 2 of 9

Image 3 of 9

Image 3 of 9

Image 4 of 9

Image 4 of 9

Image 5 of 9

Image 5 of 9

Image 6 of 9

Image 6 of 9

Image 7 of 9

Image 7 of 9

Image 8 of 9

Image 8 of 9

Image 9 of 9

Image 9 of 9

Winsun3d is using recycled construction waste and large-scale printers to build quicker

WinSun, also known as Yingchuang Building Technique (Shanghai) Co., Ltd., is a pioneering company in the field of 3D printing for construction. Founded by Ma Yihe in 2003, the company has revolutionized the construction industry by developing large-scale 3D printing technology to create buildings and structures. WinSun's mission is to make design, engineering, construction, and operation processes better, faster, and easier, aligning with the core benefits of Building Information Modeling (BIM). Core values include integrity, inclusion, excellence, and gratitude, with a purpose to lead the industry in sustainable and innovative construction practices.

Location

Headquarters: Shanghai, China.

Primary manufacturing/operations locations: Suzhou, China.

Note: Strategic locations in China to optimize local sourcing, distribution, and collaboration with industry partners.

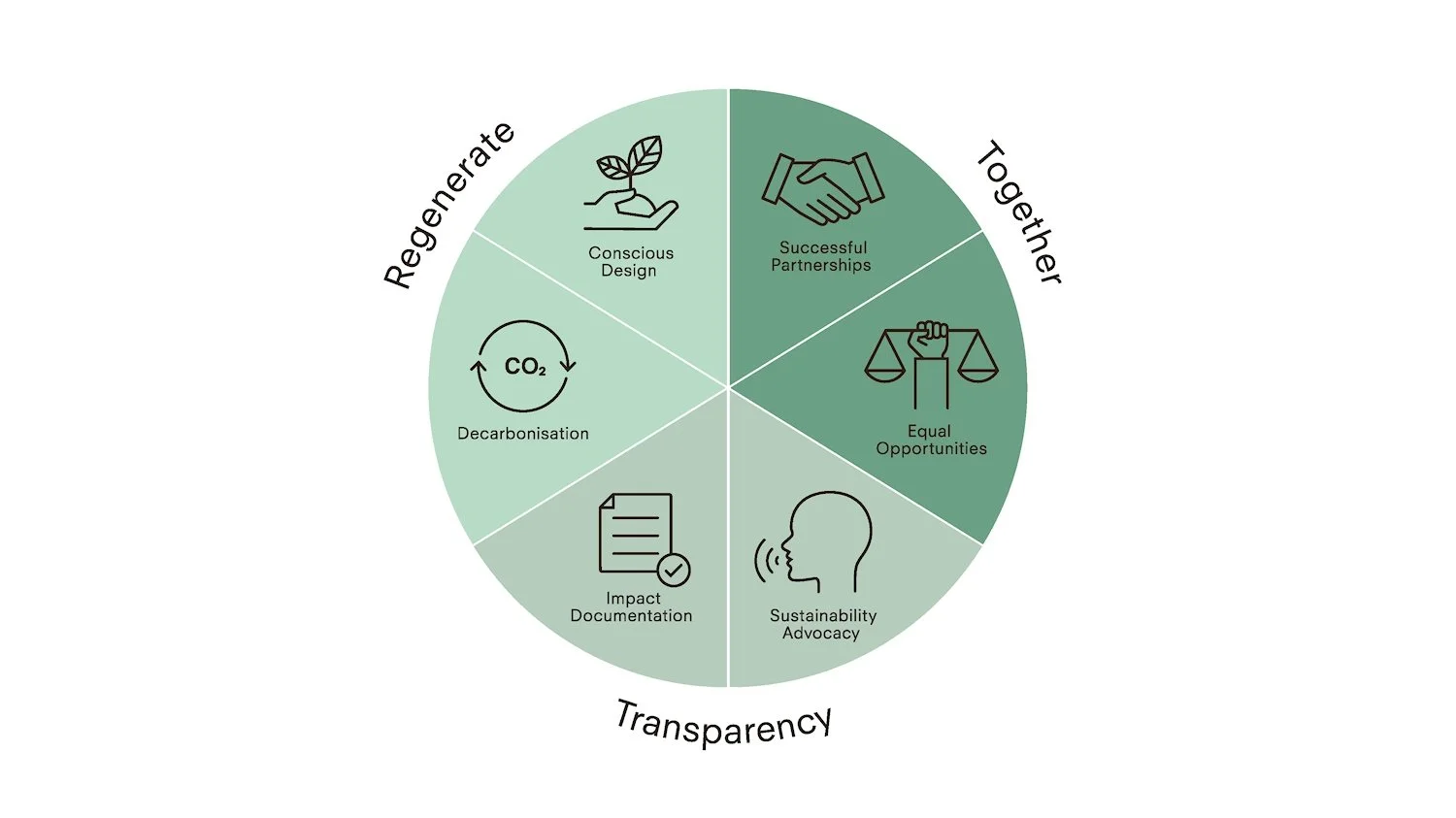

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating products that are fully recyclable.

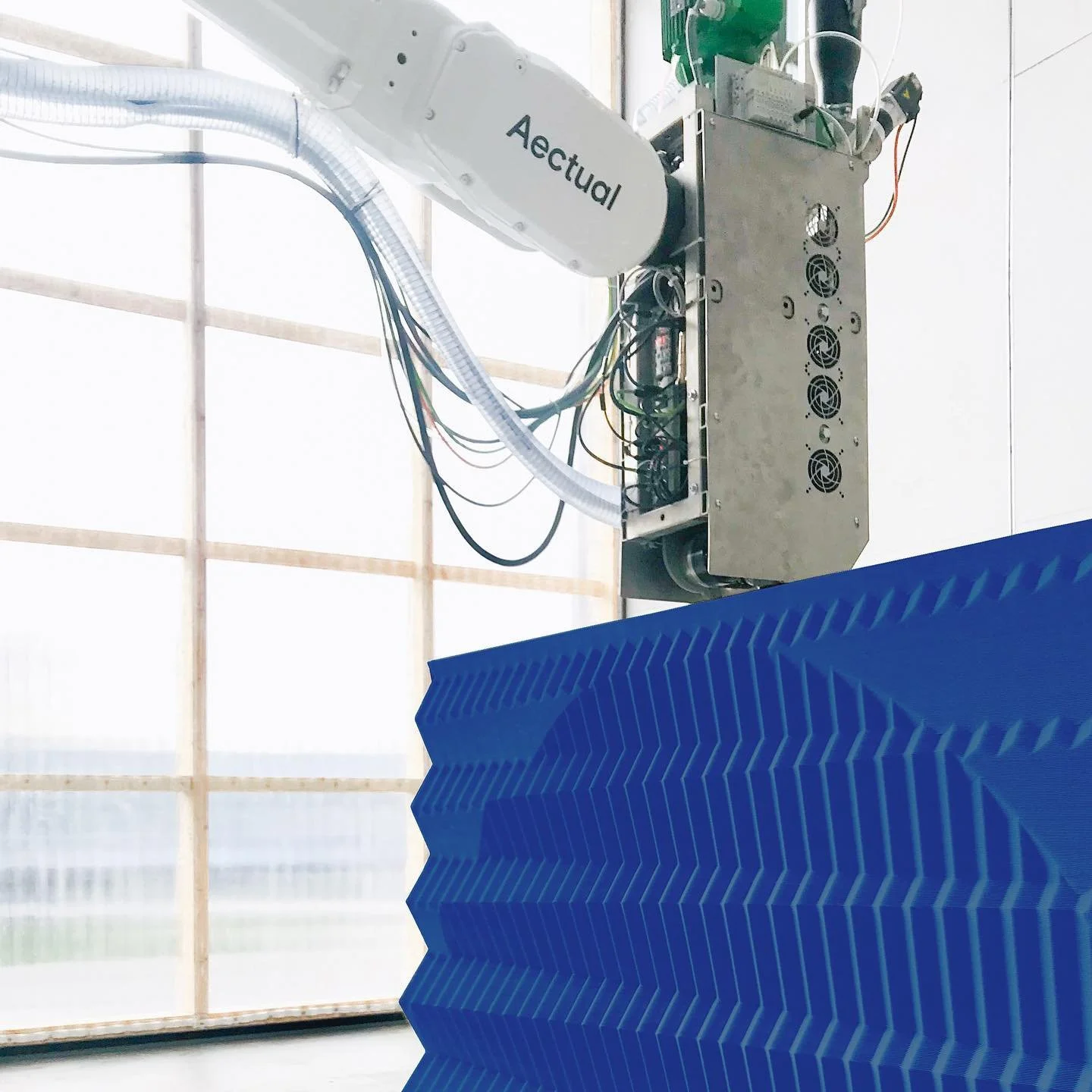

Key innovations: Development of large-scale 3D printers that use a special ink made from recycled construction waste, cement, sand, and fiber. This technology allows for the rapid construction of buildings with minimal waste and environmental impact.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on using locally sourced construction waste and sustainable production methods to minimize environmental impact and support local economies.

Pioneering Solutions

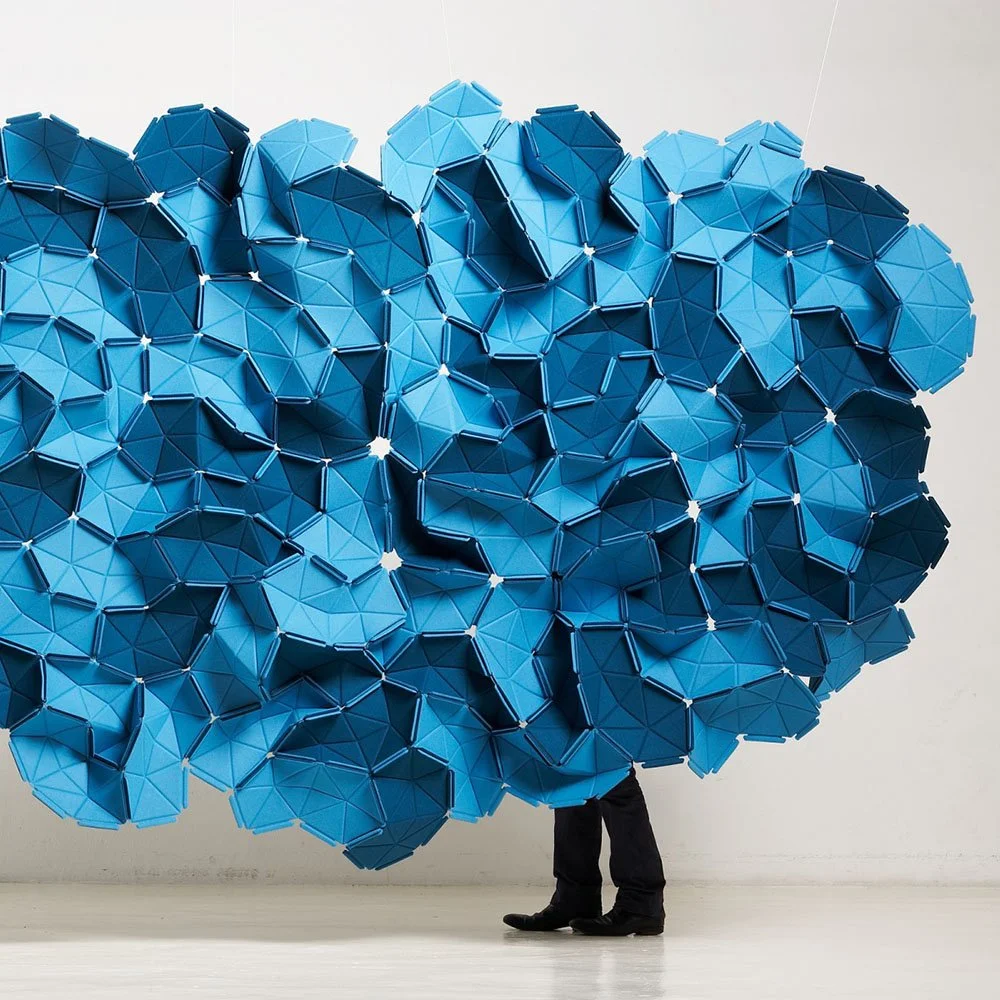

Flagship products: 3D printed buildings, including residential houses, office buildings, and public structures.

Unique value propositions: High-quality, sustainable construction solutions that prioritize circularity, material reuse, and environmental responsibility. WinSun's products are known for their durability, innovative design, and ability to significantly reduce construction time and costs.

The Regenerative Future

R&D focus areas: Advancing 3D printing technologies, optimizing production processes, and developing new applications for 3D printed construction materials.

Ambitious goals: To lead the construction industry in sustainable practices, create zero-waste products, and inspire a shift towards a regenerative built environment.

Fact Sheet

Commercial Availability: Products available globally through direct sales and partnerships with developers and governments.

Environmental Product Declaration (EPD): Information not available.

Circularity Rating: 5/5 (Strong focus on circular economy principles).

Key Certifications: Information not available.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled construction waste.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through sustainable materials and local production. The use of recycled materials and efficient construction processes significantly lowers the environmental impact.

Key Takeaway

WinSun transforms the construction industry through innovative, sustainable 3D printing solutions, setting a benchmark for circularity and environmental responsibility in modern construction.

Explore Further

WinSun website: https://www.winsun3d.com/En/

Sustainability overview: https://www.winsun3d.com/En/About/

Example product: 3D printed buildings

WinSun, also known as Yingchuang Building Technique (Shanghai) Co., Ltd., is a pioneering company in the field of 3D printing for construction. Founded by Ma Yihe in 2003, the company has revolutionized the construction industry by developing large-scale 3D printing technology to create buildings and structures. WinSun's mission is to make design, engineering, construction, and operation processes better, faster, and easier, aligning with the core benefits of Building Information Modeling (BIM). Core values include integrity, inclusion, excellence, and gratitude, with a purpose to lead the industry in sustainable and innovative construction practices.

Location

Headquarters: Shanghai, China.

Primary manufacturing/operations locations: Suzhou, China.

Note: Strategic locations in China to optimize local sourcing, distribution, and collaboration with industry partners.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating products that are fully recyclable.

Key innovations: Development of large-scale 3D printers that use a special ink made from recycled construction waste, cement, sand, and fiber. This technology allows for the rapid construction of buildings with minimal waste and environmental impact.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on using locally sourced construction waste and sustainable production methods to minimize environmental impact and support local economies.

Pioneering Solutions

Flagship products: 3D printed buildings, including residential houses, office buildings, and public structures.

Unique value propositions: High-quality, sustainable construction solutions that prioritize circularity, material reuse, and environmental responsibility. WinSun's products are known for their durability, innovative design, and ability to significantly reduce construction time and costs.

The Regenerative Future

R&D focus areas: Advancing 3D printing technologies, optimizing production processes, and developing new applications for 3D printed construction materials.

Ambitious goals: To lead the construction industry in sustainable practices, create zero-waste products, and inspire a shift towards a regenerative built environment.

Fact Sheet

Commercial Availability: Products available globally through direct sales and partnerships with developers and governments.

Environmental Product Declaration (EPD): Information not available.

Circularity Rating: 5/5 (Strong focus on circular economy principles).

Key Certifications: Information not available.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled construction waste.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through sustainable materials and local production. The use of recycled materials and efficient construction processes significantly lowers the environmental impact.

Key Takeaway

WinSun transforms the construction industry through innovative, sustainable 3D printing solutions, setting a benchmark for circularity and environmental responsibility in modern construction.

Explore Further

WinSun website: https://www.winsun3d.com/En/

Sustainability overview: https://www.winsun3d.com/En/About/

Example product: 3D printed buildings